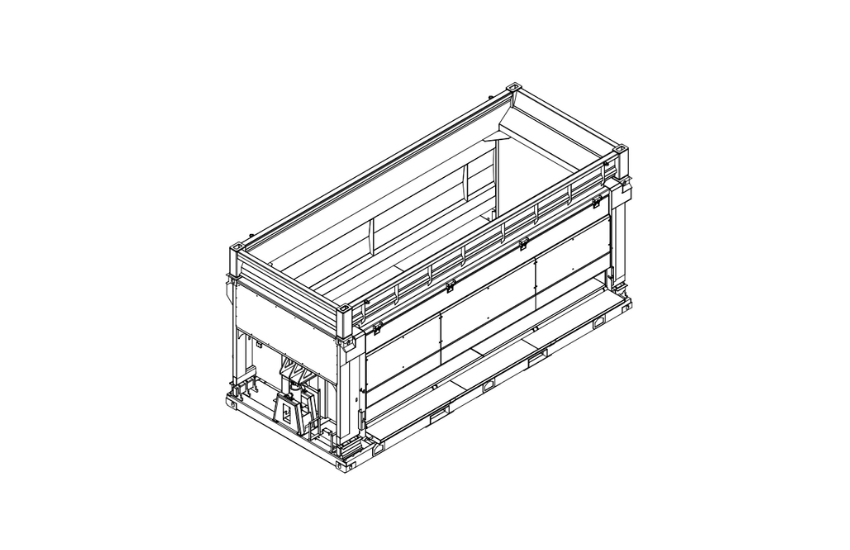

Last month, we worked with Container to assemble the KippTainer transport container. It is designed to transport bulk cargo with built-in advanced connected technology (hydraulics, electrical equipment, container tracking device) for rail and road transport, which allows users more flexibility and increases time efficiency.

The container is CSC and UIC tested, its dimensions are 6058 x 2550 x 2400 (2920) mm. The weight of the container is 6200 kg and the volume is 22-29 m3. The angle of inclination of the caisson is up to 45 degrees. It consists of a base, a caisson with upper and lower swing doors and front frames. The possibility of upgrading is an increase, which increases the volume of the container by 7 m3. The hydraulic system is connected to electronic controllers, the handling of the product body is controlled. The system enables hydraulic opening and closing of flaps, lifting of the container, positioning of the dump and protection during transport. The remote control (BRICK 09) enables the manipulation of several containers at the same time, the purpose of which is to ensure greater safety of users, and at the same time to optimize work processes over time. The container is designed to meet all the needs of the market, as its design offers an innovative and high-tech solution.

Our work on the mentioned project was drawing plans, programming and installation of electrical cabinets, installation of remote control BRICK 09 (manufacturer REMdevice) and commissioning of the entire system. During the design, preparation and installation, we also recorded a video, which you will soon be able to watch on our website and Facebook page.

Rogaška Slatina, 18. 5. 2021